Guest Post By Nisha Singh

Hey angels, how are you doing? I am writing this article after a long time. Today I am so exciting to share my experience of making lipstick in my pharma laboratory. I am a B pharma student and last week I did this practical of making lipstick in cosmetic pharma lab (I love it the most ;)) and it was amazing to make a lipstick as I am a big fan of these cute, sexy colored sticks.

In this article I will tell about the major steps I have done in manufacturing of lipsticks at my lab, its basic ingredients, difference in between the formulation of its different type and also about how it is molded in that cool shape which is easy to handle.

Before that let me tell you that this coloring stick is not as new as we think. It has been used from the rise of civilization, yes you are reading right our ancestors beauties are using this from about 5000 years, from ancients Mayans to Egyptian, from Sumerian to our very own Indus valley women used to color their lips by various means. Now let’s be on the track and find out how these sticks are made nowadays.

Manufacturing Process

Lipstick manufacturing involves three major steps

- The preparation of viscous base

- Giving it the color (it was lovely)

- Molding the blend into lipstick

Basic Ingredients

- Solid waxy base (helps to keep the shape and provide the solidity to the stick).

- Soft waxes or emollients (for the shiny finish and also provide moisture to it so that it don’t dry the lips).

- Colorants– dyes, pigments and pearlescent agents (for color purpose, may be organic but mostly artificial colors are used).

- Dyestuff solvents (they help to disperse the color into the wax).

- Perfumes (you know about it… yes for the pleasant smell that sometimes make us to eat it.. ha ha but Beauties it’s not good for health to eat the lipstick, so take care).

Process

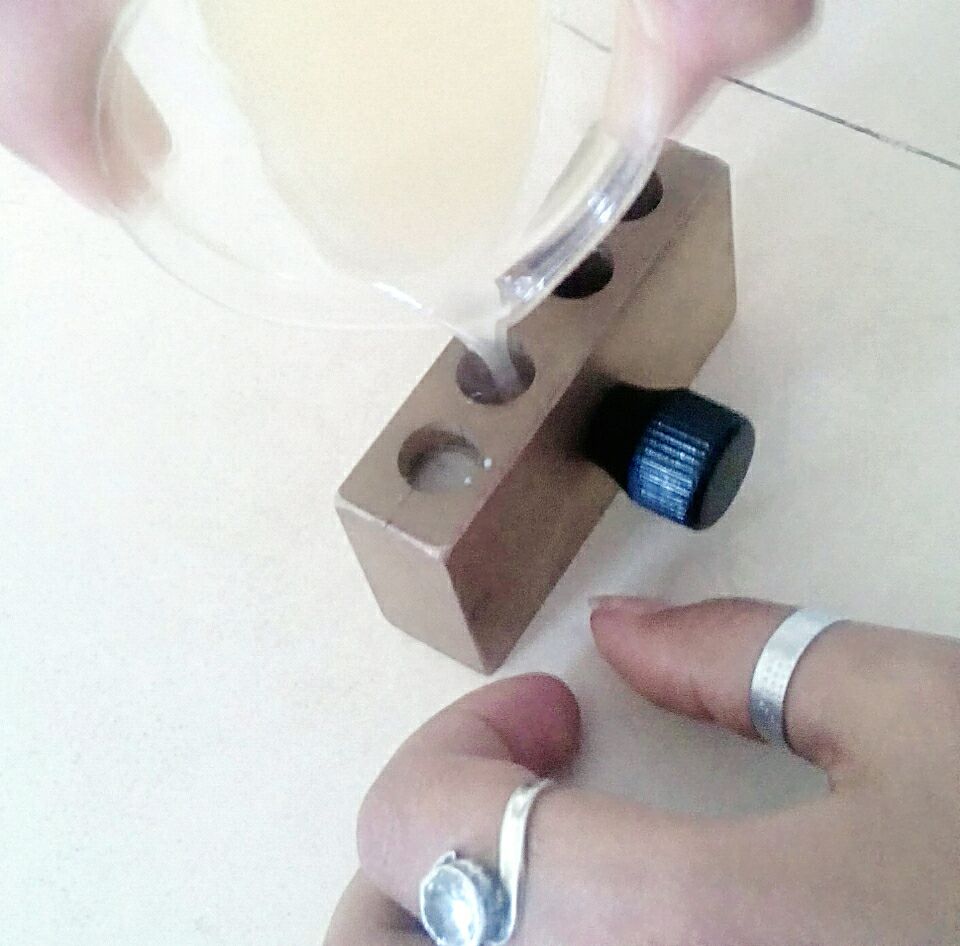

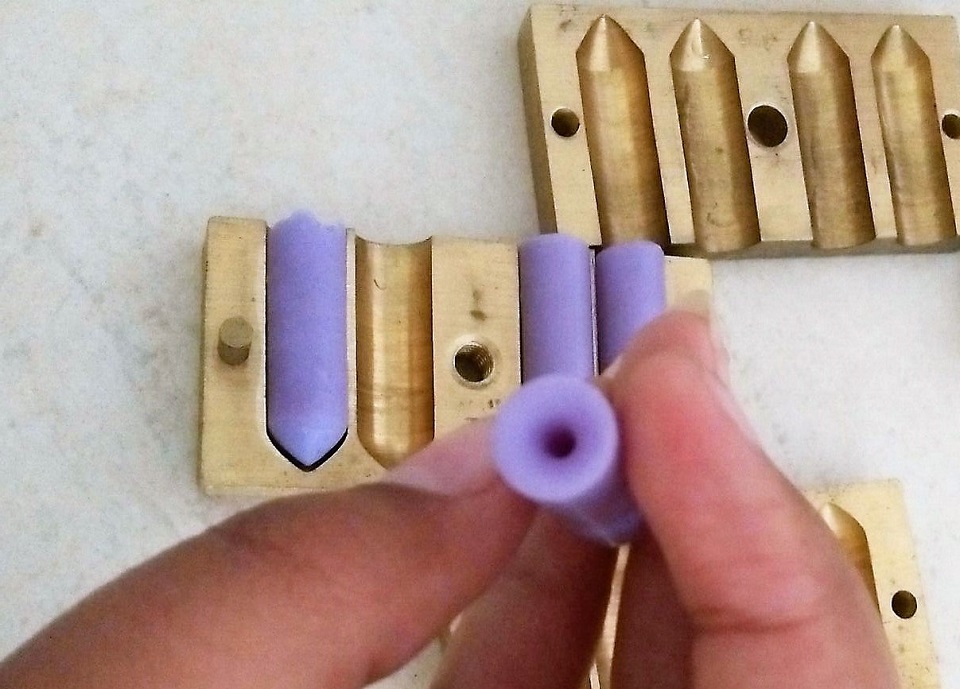

In order to make the lipstick I first melt the waxes (bee wax specially) in a water bath and then added the other ingredients like Ozokerite (a wax that occurs naturally), Hydrogenated castor and coconut oil, Cetyl ricinoleate, Glyceryl abietate (fatty acids) and antioxidant. Then the paste of the pigments and a part of castor oil made and grinded it three times on a three roll mill (a machine having three horizontal rolls used to mix and disperse the materials). The pigment paste is added to wax and mixed well. Now, the solution was cooled to 60 degree Celsius and perfumed it. Then the whole solution was poured into clean and pre lubricated moulds (an instrument that give the shape to lipstick). After cooling, it was unmolded and the cute purple stick is out (yes I made it purple by using purple dye), in industries after this process these sticks are packaged in their roll out thing for easy use.

Different Formulation

The above process and ingredients (mainly the solid wax) are used for the lipsticks used in hot countries so that they don’t flow out of lips.

Matte lipsticks have silica (filling agent) but they do not have so many emollients.

Crème lipsticks have more waxes in spite of oils while Sheer one have more oil, Long lasting lipsticks have silicone oil in them, which impresses the colors to lips.

Shimmery lipsticks contain silica, mica and synthetic pearl particles (which give them the glittery shine).

Glossy lipstick contains more fatty acids like oleyl accohol and lanolin oil which provide pigment dispersion and spread-ability hence, give a shiny finish to the lips.

Addition of antioxidants, UV filters and preservatives is necessary as it helps in increasing the shelf life of lipsticks.

So, this is all about my experience in the cosmetic lab of making lipstick. Hope you will like the information about our very lovely sticks and when next time you buy this you would know its history and it making process.

Stay Colored.

Be Alive.

6 Comments

Safiyah

Interesting post Nisha 🙂

Avanti Singla

nice one…. informative 🙂

Nisha Singh

tnku dear glad u liked it 🙂

Radhika

cool <3

Deepika Verma

looks very interesting 🙂

Sreeparna Ganguly

I didn’t know lipsticks are made in this way!!